In-depth Welding Inspection Service for High-Performance Welding

In-depth Welding Inspection Service for High-Performance Welding

Blog Article

Opening the Trick Sorts Of Welding Providers for Your Jobs

In today's landscape of varied welding services, recognizing the nuances and applications of various welding strategies is critical for effective task implementation. From commonly utilized techniques to sophisticated innovations, the world of welding supplies a spectrum of opportunities to accommodate various project demands. By untangling the crucial sorts of welding services readily available, one can navigate the ins and outs of picking the most ideal technique to make sure precision, effectiveness, and top quality in welding projects. As we begin on this expedition of welding services, a deeper understanding right into the world of welding waits for, appealing insights that can boost the end results of your projects.

Usual Welding Strategies

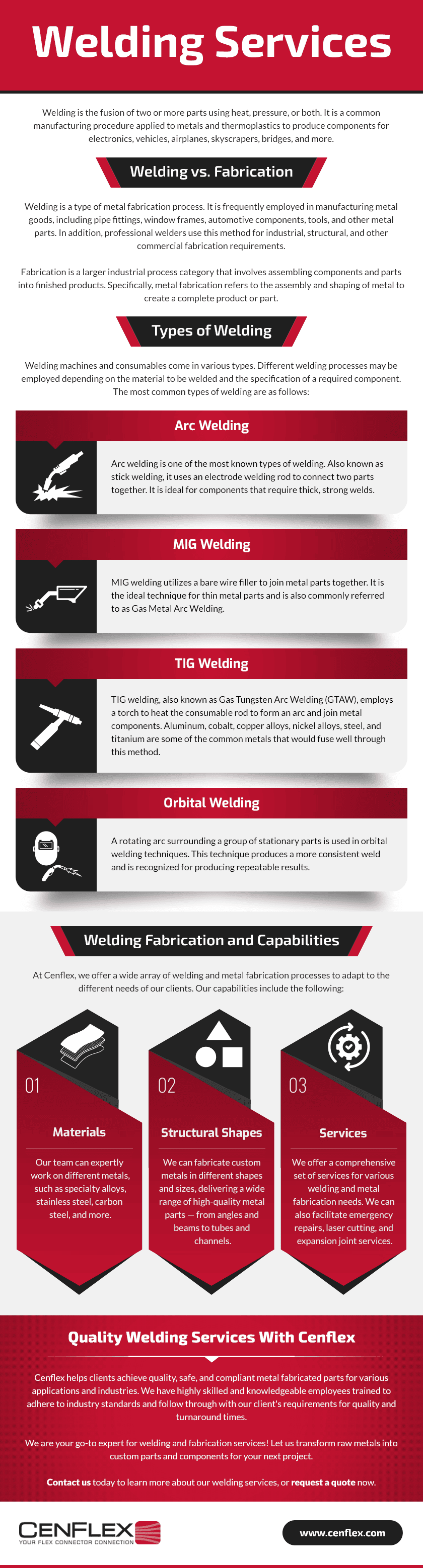

Several commonly used welding strategies play critical roles in various commercial markets. One of the most commonly made use of approaches is Gas Steel Arc Welding (GMAW), likewise understood as MIG welding.

One more preferred welding strategy is Gas Tungsten Arc Welding (GTAW), generally referred to as TIG welding. TIG welding utilizes a non-consumable tungsten electrode to create the weld and calls for a different filler material. This technique is favored for its control, ability, and precision to create top quality welds on slim materials.

Secured Metal Arc Welding (SMAW), or stick welding, is one more vital approach where a flux-coated electrode is used to produce the weld. SMAW is known for its simplicity, convenience, and suitability for exterior and on-site welding applications. These common welding methods are essential for making structures, machinery, and different equipment across markets.

Advanced Welding Procedures

Advanced welding procedures encompass sophisticated techniques that push the boundaries of typical welding methods in regards to precision, versatility, and efficiency. One such procedure is laser light beam welding, which makes use of a focused beam to sign up with metals with minimal heat-affected zones, making it perfect for fragile or high-precision projects. In addition, electron beam of light welding employs a high-velocity electron light beam to develop deep welds in thick materials, providing phenomenal toughness and quality.

Furthermore, rubbing mix welding is a solid-state joining process that utilizes a rotating device to create frictional warmth, bonding materials without melting them. This technique is particularly valuable for signing up with light-weight alloys with remarkable mechanical properties. One more innovative technique is ultrasonic welding, where high-frequency ultrasonic resonances are made use of to produce solid-state welds in plastics, steels, and other materials, providing tidy and quick signing up with solutions.

These advanced welding processes accommodate a varied series of industrial demands, giving efficient, top quality, and accurate options for various tasks, from aerospace components to auto components and past.

Specialized Welding Applications

Automated Welding Solutions

In contemporary industrial settings, the application of automated welding remedies has actually transformed production procedures by boosting performance and precision. Automated welding systems utilize sophisticated innovations such as robotics, computer system mathematical control (CNC), and artificial intelligence to carry out welding jobs official source with marginal human treatment (Welding Inspection Service). These systems offer various benefits, including boosted efficiency, improved weld high quality, and minimized manufacturing costs

One key advantage of automated welding remedies is their capacity to continually produce high-grade welds, leading to improved general product high quality. Furthermore, these systems can operate constantly, 24/7, without the need for breaks, resulting in higher result degrees and faster job completion times. By making use of automated welding options, business can likewise mitigate the dangers linked with human mistake, making certain better accuracy and repeatability in the welding process.

Additionally, automated welding services are highly versatile and versatile to numerous welding applications, from detailed elements to large-scale frameworks. Whether in vehicle manufacturing, aerospace sectors, or building and construction jobs, the integration of automated welding systems offers a competitive edge by streamlining procedures and providing superior welding outcomes.

Cutting-edge Welding Technologies

The advancement of automated welding services has actually paved the method for the integration and advancement of ingenious welding modern technologies in contemporary industrial applications. One such innovative technology is laser beam welding, which makes use of an extremely focused beam of light to join steel components with accuracy and efficiency. This technique is particularly valuable for jobs requiring complex welds on materials with high melting factors or for applications where very little heat-affected zones are crucial.

One more cutting-edge welding innovation gaining popularity is friction stir welding (FSW), a solid-state signing up with process that creates high-strength bonds by producing frictional warm between two pieces of steel. FSW is widely utilized in sectors such as aerospace and automotive for its ability to generate welds with remarkable mechanical homes and boosted structural integrity.

In addition, electron light beam welding (EBW) is an innovative technique that utilizes a beam of light of high-velocity electrons to develop accurate, deep welds in metal components. This technology is preferred for its capacity to bond dissimilar metals and materials with differing densities effectively. As markets remain to require greater top quality and efficiency in welding procedures, these innovative innovations are poised to play a considerable duty in forming the future of commercial welding applications.

Final Thought

Finally, comprehending the crucial types of welding services is vital for effectively finishing a variety of tasks. From usual welding techniques to sophisticated procedures, specialized applications, automated options, and ingenious modern technologies, each technique offers distinct advantages and applications. By acquainting yourself with these numerous welding choices, you can choose the most ideal technique for your details job requirements and achieve top notch outcomes.

In today's landscape of diverse welding solutions, comprehending the nuances and applications of various welding strategies is paramount for effective task implementation. By untangling you could try this out the key kinds of welding services available, one can browse the details of picking the most ideal technique to ensure precision, performance, and high quality in welding jobs. As we get started on this expedition of welding services, a much deeper understanding into the globe of welding waits for, promising understandings that can elevate the outcomes of your projects.

Report this page